|

||||||||||||

|

|

|

Nuclear Power Plants

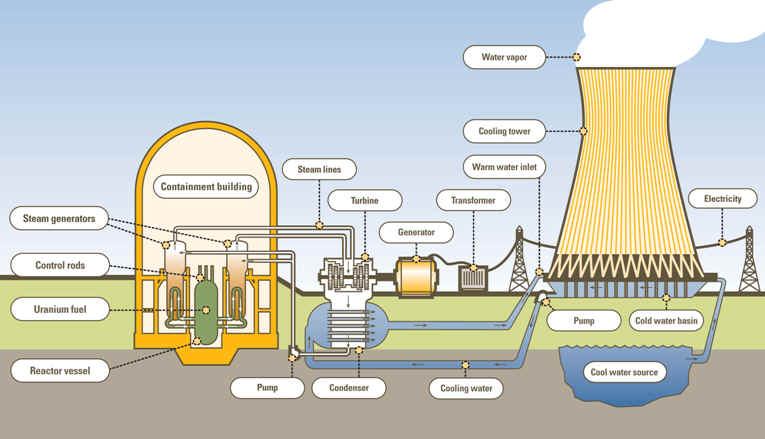

Nuclear power plants use the heat generated from nuclear fission in a contained environment to convert water to steam, which powers generators to produce electricity.

Nuclear Power Plant Buildings

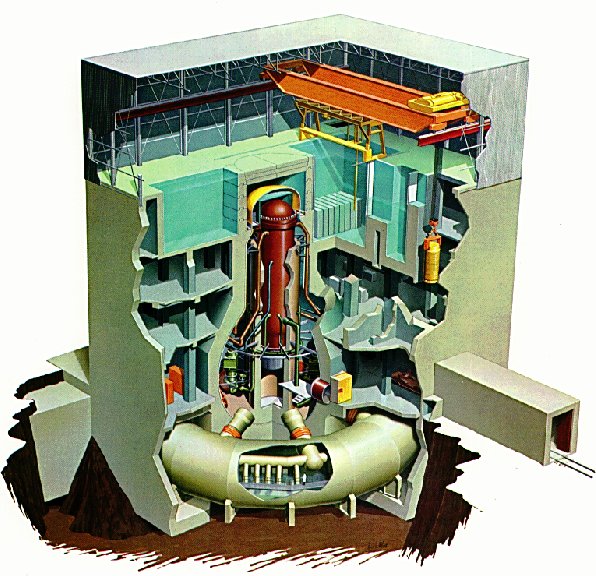

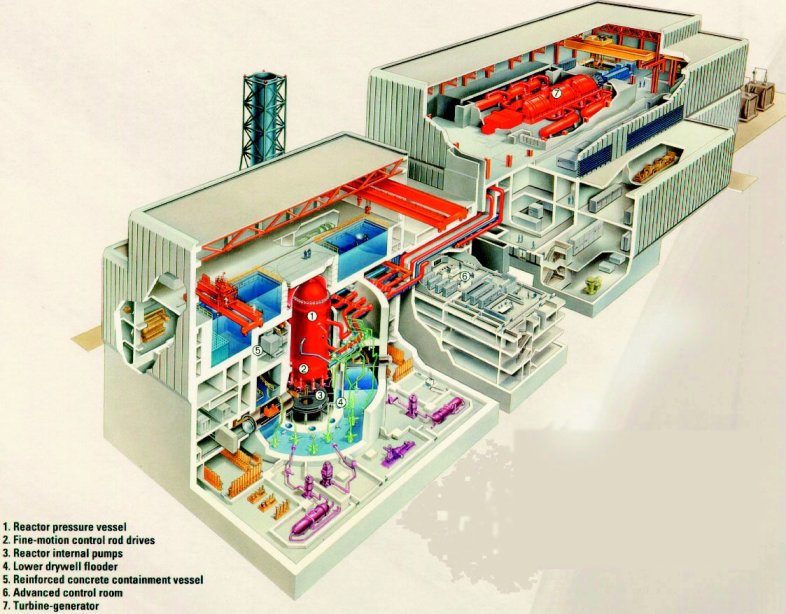

Containment or Drywell Building - a building designed to sustain pressures of about 50 pounds per square inch. Normally houses the reactor and the related cooling system that contains highly radioactive fluids. Building is of steel construction. Sometimes the building is surrounded by a concrete structure that is designed for much lower pressures (3 pounds per square inch). The area between the steel and concrete building is called the annulus. Designs vary. At one facility there are 4 1/2 foot thick concrete walls reinforced with steel. The dome is 2 1/2 feet thick and the base 12 feet thick. The containment is the 3rd fission product barrier. In BWRs, the drywell is located in the reactor building.

Auxiliary or Reactor Building ( a building separate from the containment that houses much of the support equipment that may contain radioactive liquids and gases. Emergency equipment is also normally located in this building.

The turbine hall of Bruce Power's Bruce A nuclear power plant in Ontario, Canada. [Image: Bruce Power] Turbine Building - a building that houses the turbine, generator, condenser, condensate and feedwater systems. Intake Structure or Screenhouse - a building that houses the circulating water pumps used to pump water from the river, lake, sea for cooling the condenser. Trash racks and traveling screens also remove debris to clean the water so that it can pass through the condenser tubes.

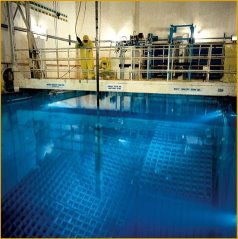

Fuel Building - a building separate from the containment that is used to spent fuel assemblies in steel racks in a large 40 foot deep storage pool. Casks for shipping or onsite dry storage of spent fuel assemblies will be loaded (or unloaded in this pool). A new fuel storage area is provided for receipt of new assemblies and storage prior to going into the containment and subsequently into the reactor during a refueling.

Diesel Generator Building - a building used to house the diesel generators and supporting systems (air, water, radiator fans, fuel oil, lubricating oil, air conditioning, and ventilation). In some cases, related electrical switchgear for distributing electrical power produced by the diesel generator. The Diesel generators that provide backup electrical power to safety and non-safety systems. In some plants separate buildings or areas within the buildings mentioned above may house the following:

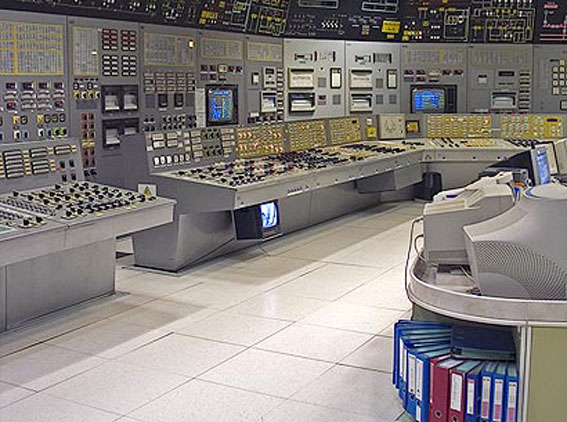

Control room at Slovenské elektrárne's Bohunice nuclear power plant in Slovakia. [Image: Slovenské elektrárne]

Types of Nuclear Reactors

Boiling Water Reactor (BWR) The boiling water reactor operates in essentially the same way as a fossil fuel generating plant. Neither of these types of power plants have a steam generator. Instead, water in the BWR boils inside the pressure vessel and the steam water mixture is produced when very pure water (reactor coolant) moves upward through the core absorbing heat. The water boils and produces steam. When the steam rises to the top of the pressure vessel, water droplets are removed, the steam is sent to the turbine generator to turn the turbine.A BWR has many similarities to a PWR but there is only one circuit with water at lower pressure so that it boils in the core at about 285°C. The water in the top part of the core is in the form of steam, which has a lower moderating effect. The steam passes directly to the turbines, which are thus part of the reactor circuit. Also, the control rods enter from below.

Pressurized Water Reactor (PWR)

The pressurized water reactor differs from the BWR in that the steam to run the turbine is produced in a steam generator. Water boils at 212°F or 100°C. If a lid is tightly placed over a pot of boiling water (a pressure cooker), the pressure inside the pot will increase because the steam cannot escape. As the pressure increases, so does the temperature of the water in the pot. In the PWR plant, a pressurizer unit keeps the water that is flowing through the reactor vessel under very high pressure to prevent it from boiling. The hot water then flows into the steam generator where it is converted to steam. The steam passes through the turbine which produces electricity. About 60% of the world’s commercial power reactors are Pressurized Water Reactors (PWRs).

CANDU is a pressurized heavy water reactor operated on natural uranium fuel (U-238) and uses heavy water (D2O) as coolant and moderator. CANDU is an acronym for CANada Deuterium Uranium. The CANDU reactor is capable of on-line refuelling during operation.

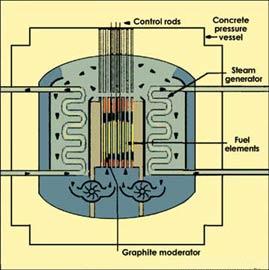

RBMK is a type of pressure tube reactor designed in the former Soviet Union, which uses ordinary boiling water as the coolant and graphite as the moderator. This type of reactor is capable of on-line refuelling. The reactor involved in the Chernobyl accident belongs to this type. Other types of reactors:

United States

There are 65 Nuclear Power Plants in The United States that have 104 commercial nuclear generating units that are fully licensed by the U.S. Nuclear Regulatory Commission (NRC). Of these 104 reactors, 69 are categorized a pressurized water reactors (PWRs) totaling 65,100 net megawatts (electric) and 35 units are boiling water reactors (BWR) totaling 32,300 net megawatts (electric). Although the United States has the most nuclear capacity of any nation, no new commercial reactor has come on line since May 1996. The current Administration has been supportive of nuclear expansion, emphasizing its importance in maintaining a diverse energy supply. The last reactor to come on line in the United States was the Watt’s Bar reactor in Tennessee, owned and operated by the Tennessee Valley Authority. It began commercial service in May 1996. Nevertheless, US commercial nuclear capacity has increased in recent years through a combination of license extensions and uprating (upgrading) of existing reactors.

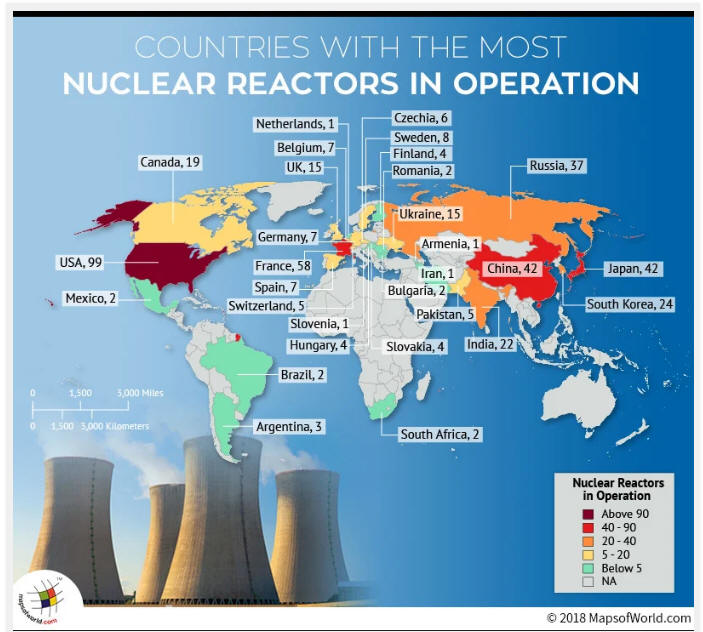

World Nuclear Power Reactors

There are 32 countries in which nuclear power plants operate

Nuclear power by country - Wikipedia

Credit:Argonne National Laboratory, World Nuclear Association,IAEA |