|

||||||||||||

|

|

|

Three Mile Island

Report

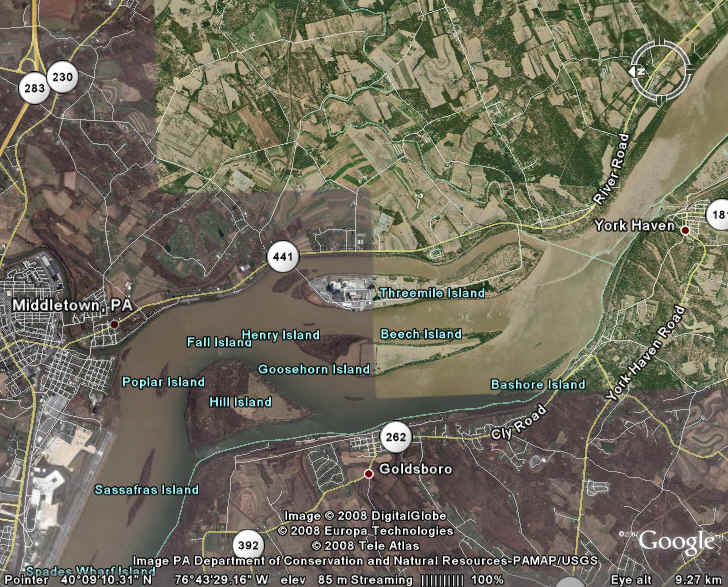

The accident at the Three Mile Island Unit 2 (TMI-2) nuclear power plant near Middletown, Pennsylvania, on March 28, 1979, was the most serious in U.S. commercial nuclear power plant operating history, even though it led to no deaths or injuries to plant workers or members of the nearby community.

But it brought about sweeping changes involving emergency response planning, reactor operator training, human factors engineering, radiation protection, and many other areas of nuclear power plant operations. It also caused the U.S. Nuclear Regulatory Commission to tighten and heighten its regulatory oversight. Resultant changes in the nuclear power industry and at the NRC had the effect of enhancing safety. The sequence of certain events - - equipment malfunctions, design related problems and worker errors - - led to significant damage to the TMI-2 reactor core but only very small off-site releases of radioactivity.

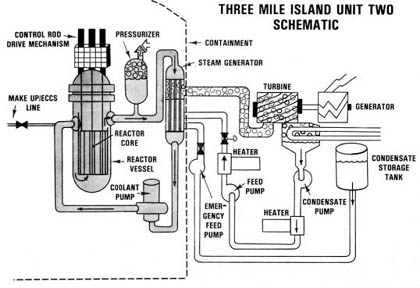

Summary of Events The accident began about 4:00 a.m. on March 28, 1979, when the plant experienced a failure in the secondary, non-nuclear section of the plant. The main feedwater pumps stopped running, caused by either a mechanical or electrical failure, which prevented the steam generators from removing heat. First the turbine, then the reactor automatically shut down. Immediately, the pressure in the primary system (the nuclear portion of the plant) began to increase. In order to prevent that pressure from becoming excessive, the pressurizer relief valve (a valve located at the top of the pressurizer) opened. The valve should have closed when the pressure decreased by a certain amount, but it did not. Signals available to the operator failed to show that the valve was still open. As a result, the stuck-open valve caused the pressure to continue to decrease in the system.

World Nuclear Association Graphic Meanwhile, another problem appeared elsewhere in the plant. The emergency feedwater system (backup to main feedwater) was tested 42 hours prior to the accident. As part of the test, a valve is closed and then reopened at the end of the test. But this time, through either an administrative or human error, the valve was not reopened - - preventing the emergency feedwater system from functioning. The valve was discovered closed about eight minutes into the accident. Once it was reopened, the emergency feedwater system began to work correctly, allowing cooling water to flow into the steam generators. As the system pressure in the primary system continued to decrease, voids (areas where no water is present) began to form in portions of the system other than the pressurizer. Because of these voids, the water in the system was redistributed and the pressurizer became full of water. The level indicator, which tells the operator the amount of coolant capable of heat removal, incorrectly indicated the system was full of water. Thus, the operator stopped adding water. He was unaware that, because of the stuck valve, the indicator can, and in this instance did, provide false readings. Because adequate cooling was not available, the nuclear fuel overheated to the point where some of the zirconium cladding (the long metal tubes or jackets which hold the nuclear fuel pellets) reacted with the water and generated hydrogen. This hydrogen was released into the reactor containment building. By March 30, two days after the start of the chain of events, some hydrogen remained within the primary coolant system in the vessel surrounding the reactor, forming a "hydrogen bubble" above the reactor core. The concern was that if reactor pressure decreased, the hydrogen bubble would expand and thus interfere with the flow of cooling water through the core. Over the next few days, the bubble was reduced by "degassing" the pressurizer -- adjusting air and water pressure. Without water to cool it, and with the top of the reactor core uncovered, the primary damage to the reactor occurred two to three hours into the accident. Although no "meltdown" occurred in the classic sense of the word, in that fuel did not "melt" through the floor beneath the containment or through the steel reactor vessel, a significant amount of fuel did in fact melt. Radioactivity in the reactor coolant increased dramatically, and there were small leaks in the reactor coolant system which caused high radiation levels in other parts of the plant and small releases into the environment. Shortly after the accident began, some of the water, carrying fuel debris and fission products, escaped from the reactor coolant system and flowed into the reactor building basement. By the time the accident had ended, the water in the basement had been heated by residual heat from the reactor vessel, evaporated, condensed on the walls, and drained down onto the floors and back into the basement. The radionuclides then permeated into the porous surfaces of concrete and layers of iron which later became corroded (this area of the plant became a major focus of the subsequent clean-up and decontamination).

Response to the accident was swift. The NRC's regional office in King of Prussia, Pennsylvania, was notified at 7:45 a.m. on March 28. By 8:00, the NRC headquarters in Washington, D.C. was alerted and the NRC Operations Center in Bethesda, Maryland, was activated. The regional office promptly dispatched the first team of inspectors to the site and other agencies, such as the Department of Energy, and the Environmental Protection Agency, also mobilized their response teams. Helicopters hired by TMI's owner, General Public Utilities Nuclear, and the Department of Energy were sampling radioactivity in the atmosphere above the plant by midday. A team from the Brookhaven National Laboratory was also sent to assist in radiation monitoring. At 9:15 a.m., the White House was notified and at 11:00 a.m., all non-essential personnel were ordered off the plant's premises.

Drawing from Metropolitan Edison Co. "Report to the Met-Ed Community" May 30, 1979 From the early stages of the accident, low levels of radioactive gas, mostly in the form of xenon, continued to be released to the environment. At the time, efforts to halt the releases were unsuccessful and there was some fear of an explosion from the buildup of hydrogen - -fortunately, this did not occur.

Harold Denton, Director of the Office of Nuclear Reactor Regulation and Richard L. Thornburgh

However, on Friday, March 30, Governor Thornburgh of Pennsylvania ordered a precautionary evacuation of preschool children and pregnant women from within the 5-mile zone nearest the plant, and suggested that people living within 10 miles of the plant stay inside and keep their windows closed. Most evacuees had returned to their homes by April 4 -- by that time, the situation at the reactor had been brought under control.

The American Nuclear Insurers, an organization made up of nuclear insurance firms, had already begun distributing checks to evacuees to cover hotel and meal expenses, and was beginning to handle claims for property and liability losses.

Health EffectsDetailed studies of the radiological consequences of the accident have been conducted by the NRC, the Environmental Protection Agency, the Department of Health, Education and Welfare (now Health and Human Services) , the Department of Energy, and the State of Pennsylvania. Several independent studies have also been conducted. Estimates are that the average dose to about 2 million people in the area was about only about 1 millirem. To put this into context, exposure from a full set of chest x-rays is about 6 millirem. Compared to the natural radioactive background dose of about 100-125 millirem per year for the area, the collective dose to the community from the accident was very small. The maximum dose to a person at the site boundary would have been less than 100 millirem. In the months following the accident, although questions were raised about possible adverse effects from radiation on human, animal, and plant life in the TMI area, none could be directly correlated to the accident. Thousands of environmental samples of air, water, milk, vegetation, soil, and foodstuffs were collected by various groups monitoring the area. Very low levels of radionuclides could be attributed to releases from the accident. However, comprehensive investigations and assessments by several well-respected organizations have concluded that in spite of serious damage to the reactor, most of the radiation was contained and that the actual release had negligible effects on the physical health of individuals or the environment. Impact of the AccidentToday, the TMI-2 reactor is permanently shut down and defueled, with the reactor coolant system decontaminated, the radioactive liquids treated, most components shipped to a licensed low-level waste disposal site, with the remainder of the site being monitored. The owner, General Public Utilities Nuclear Corporation, says it will keep the facility in long-term storage until the operating license for the TMI-1 plant expires in 2014, at which time both plants will be decommissioned. The causes of the accident continue to be debated to this day. However, based on a series of investigations, the main factors appear to have been a combination of personnel error, design deficiencies, and component failures. There is no doubt that the accident at Three Mile Island permanently changed both the nuclear industry and the NRC. Public fear and distrust increased, NRC's regulations and oversight became broader and more robust, and management of the plants was scrutinized more carefully. The problems identified from careful analysis of the events during those days have led to permanent and sweeping changes in how NRC regulates its licensees - - which, in turn, has strengthened public health and safety. Here are some of the major changes which have occurred since the accident:

Backgrounder on the Three Mile Island Accident The accident at the Three Mile Island Unit 2 (TMI‑2) nuclear power plant near Middletown, Pa., on March 28, 1979, was the most serious in U.S. commercial nuclear power plant operating history, even though it led to no deaths or injuries to plant workers or members of the nearby community. But it brought about sweeping changes involving emergency response planning, reactor operator training, human factors engineering, radiation protection, and many other areas of nuclear power plant operations. It also caused the U.S. Nuclear Regulatory Commission to tighten and heighten its regulatory oversight. Resultant changes in the nuclear power industry and at the NRC had the effect of enhancing safety. The sequence of certain events – equipment malfunctions, design-related problems and worker errors – led to a partial meltdown of the TMI‑2 reactor core but only very small off‑site releases of radioactivity. Summary of EventsThe accident began about 4:00 a.m. on March 28, 1979, when the plant experienced a failure in the secondary, non‑nuclear section of the plant. The main feedwater pumps stopped running, caused by either a mechanical or electrical failure, which prevented the steam generators from removing heat. First the turbine, then the reactor automatically shut down. Immediately, the pressure in the primary system (the nuclear portion of the plant) began to increase. In order to prevent that pressure from becoming excessive, the pilot-operated relief valve (a valve located at the top of the pressurizer) opened. The valve should have closed when the pressure decreased by a certain amount, but it did not. Signals available to the operator failed to show that the valve was still open. As a result, cooling water poured out of the stuck-open valve and caused the core of the reactor to overheat. As coolant flowed from the core through the pressurizer, the instruments available to reactor operators provided confusing information. There was no instrument that showed the level of coolant in the core. Instead, the operators judged the level of water in the core by the level in the pressurizer, and since it was high, they assumed that the core was properly covered with coolant. In addition, there was no clear signal that the pilot-operated relief valve was open. As a result, as alarms rang and warning lights flashed, the operators did not realize that the plant was experiencing a loss-of-coolant accident. They took a series of actions that made conditions worse by simply reducing the flow of coolant through the core. Because adequate cooling was not available, the nuclear fuel overheated to the point at which the zirconium cladding (the long metal tubes which hold the nuclear fuel pellets) ruptured and the fuel pellets began to melt. It was later found that about one-half of the core melted during the early stages of the accident. Although the TMI-2 plant suffered a severe core meltdown, the most dangerous kind of nuclear power accident, it did not produce the worst-case consequences that reactor experts had long feared. In a worst-case accident, the melting of nuclear fuel would lead to a breach of the walls of the containment building and release massive quantities of radiation to the environment. But this did not occur as a result of the three Mile Island accident. The accident caught federal and state authorities off-guard. They were concerned about the small releases of radioactive gases that were measured off-site by the late morning of March 28 and even more concerned about the potential threat that the reactor posed to the surrounding population. They did not know that the core had melted, but they immediately took steps to try to gain control of the reactor and ensure adequate cooling to the core. The NRC=s regional office in King of Prussia, Pa., was notified at 7:45 a.m. on March 28. By 8:00, NRC Headquarters in Washington, D.C., was alerted and the NRC Operations Center in Bethesda, Md., was activated. The regional office promptly dispatched the first team of inspectors to the site and other agencies, such as the Department of Energy and the Environmental Protection Agency, also mobilized their response teams. Helicopters hired by TMI’s owner, General Public Utilities Nuclear, and the Department of Energy were sampling radioactivity in the atmosphere above the plant by midday. A team from the Brookhaven National Laboratory was also sent to assist in radiation monitoring. At 9:15 a.m., the White House was notified and at 11:00 a.m., all non‑essential personnel were ordered off the plant’s premises. By the evening of March 28, the core appeared to be adequately cooled and the reactor appeared to be stable. But new concerns arose by the morning of Friday, March 30. A significant release of radiation from the plant=s auxiliary building, performed to relieve pressure on the primary system and avoid curtailing the flow of coolant to the core, caused a great deal of confusion and consternation. In an atmosphere of growing uncertainty about the condition of the plant, the governor of Pa., Richard L. Thornburgh, consulted with the NRC about evacuating the population near the plant. Eventually, he and NRC Chairman Joseph Hendrie agreed that it would be prudent for those members of society most vulnerable to radiation to evacuate the area. Thornburgh announced that he was advising pregnant women and pre-school-age children within a 5-mile radius of the plant to leave the area. Within a short time, the presence of a large hydrogen bubble in the dome of the pressure vessel, the container that holds the reactor core, stirred new worries. The concern was that the hydrogen bubble might burn or even explode and rupture the pressure vessel. In that event, the core would fall into the containment building and perhaps cause a breach of containment. The hydrogen bubble was a source of intense scrutiny and great anxiety, both among government authorities and the population, throughout the day on Saturday, March 31. The crisis ended when experts determined on Sunday, April 1, that the bubble could not burn or explode because of the absence of oxygen in the pressure vessel. Further, by that time, the utility had succeeded in greatly reducing the size of the bubble. Health EffectsDetailed studies of the radiological consequences of the accident have been conducted by the NRC, the Environmental Protection Agency, the Department of Health, Education and Welfare (now Health and Human Services), the Department of Energy, and the State of Pa.. Several independent studies have also been conducted. Estimates are that the average dose to about 2 million people in the area was only about 1 millirem. To put this into context, exposure from a chest x‑ray is about 6 millirem. Compared to the natural radioactive background dose of about 100‑125 millirem per year for the area, the collective dose to the community from the accident was very small. The maximum dose to a person at the site boundary would have been less than 100 millirem. In the months following the accident, although questions were raised about possible adverse effects from radiation on human, animal, and plant life in the TMI area, none could be directly correlated to the accident. Thousands of environmental samples of air, water, milk, vegetation, soil, and foodstuffs were collected by various groups monitoring the area. Very low levels of radionuclides could be attributed to releases from the accident. However, comprehensive investigations and assessments by several well‑respected organizations have concluded that in spite of serious damage to the reactor, most of the radiation was contained and that the actual release had negligible effects on the physical health of individuals or the environment. Impact of the AccidentThe accident was caused by a combination of personnel error, design deficiencies, and component failures. There is no doubt that the accident at Three Mile Island permanently changed both the nuclear industry and the NRC. Public fear and distrust increased, NRC’s regulations and oversight became broader and more robust, and management of the plants was scrutinized more carefully. The problems identified from careful analysis of the events during those days have led to permanent and sweeping changes in how NRC regulates its licensees – which, in turn, has reduced the risk to public health and safety. Here are some of the major changes which have occurred since the accident:

Current StatusToday, the TMI‑2 reactor is permanently shut down and defueled, with the reactor coolant system drained, the radioactive water decontaminated and evaporated, radioactive waste shipped off‑site to an appropriate disposal site, reactor fuel and core debris shipped off‑site to a Department of Energy facility, and the remainder of the site being monitored. In 2001, FirstEnergy acquired TMI-2 from GPU. FirstEnergy has contracted the monitoring of TMI-2 to Exelon, the current owner and operator of TMI-1. The companies plan to keep the TMI-2 facility in long‑term, monitored storage until the operating license for the TMI‑1 plant expires, at which time both plants will be decommissioned. Below is a chronology of highlights of the TMI‑2 cleanup from 1980 through 1993.

Glossary Background radiation - The radiation in the natural environment, including cosmic rays and radiation from the naturally radioactive elements, both outside and inside the bodies of humans and animals. The usually quoted average individual exposure from background radiation is 300 millirem per year. Cladding - The thin-walled metal tube that forms the outer jacket of a nuclear fuel rod. It prevents the corrosion of the fuel by the coolant and the release of fission products in the coolants. Aluminum, stainless steel and zirconium alloys are common cladding materials. Emergency feedwater system - Backup feedwater supply used during nuclear plant startup and shutdown; also known as auxiliary feedwater. Fuel rod - A long, slender tube that holds fuel (fissionable material) for nuclear reactor use. Fuel rods are assembled into bundles called fuel elements or fuel assemblies, which are loaded individually into the reactor core. Containment - The gas-tight shell or other enclosure around a reactor to confine fission products that otherwise might be released to the atmosphere in the event of an accident. Coolant - A substance circulated through a nuclear reactor to remove or transfer heat. The most commonly used coolant in the U.S. is water. Other coolants include air, carbon dioxide, and helium. Core - The central portion of a nuclear reactor containing the fuel elements, and control rods. Decay heat - The heat produced by the decay of radioactive fission products after the reactor has been shut down. Decontamination - The reduction or removal of contaminating radioactive material from a structure, area, object, or person. Decontamination may be accomplished by (1) treating the surface to remove or decrease the contamination; (2) letting the material stand so that the radioactivity is decreased by natural decay; and (3) covering the contamination to shield the radiation emitted. Feedwater - Water supplied to the steam generator that removes heat from the fuel rods by boiling and becoming steam. The steam then becomes the driving force for the turbine generator. Nuclear Reactor - A device in which nuclear fission may be sustained and controlled in a self-supporting nuclear reaction. There are several varieties, but all incorporate certain features, such as fissionable material or fuel, a moderating material (to control the reaction), a reflector to conserve escaping neutrons, provisions for removal of heat, measuring and controlling instruments, and protective devices. Pressure Vessel - A strong-walled container housing the core of most types of power reactors. Pressurizer - A tank or vessel that controls the pressure in a certain type of nuclear reactor. Primary System - The cooling system used to remove energy from the reactor core and transfer that energy either directly or indirectly to the steam turbine. Radiation - Particles (alpha, beta, neutrons) or photons (gamma) emitted from the nucleus of an unstable atom as a result of radioactive decay. Reactor Coolant System - (see primary system) Secondary System - The steam generator tubes, steam turbine, condenser and associated pipes, pumps, and heaters used to convert the heat energy of the reactor coolant system into mechanical energy for electrical generation. Steam Generator - The heat exchanger used in some reactor designs to transfer heat from the primary (reactor coolant) system to the secondary (steam) system. This design permits heat exchange with little or no contamination of the secondary system equipment. Turbine - A rotary engine made with a series of curved vanes on a rotating shaft. Usually turned by water or steam. Turbines are considered to be the most economical means to turn large electrical generators.

Credit: U.S. Department of Energy, International Atomic Energy Agency, U.S. Nuclear Regulatory Commission, Nuclear Science Division ---- Lawrence Berkeley National Laboratory, Penn State Radiation Science and Engineering Center, American Nuclear Society, European Commision |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||