|

||||||||||||

|

|

|

U.S. Oil and Gas Pipelines The first oil pipeline in the United States was built in 1865, following the discovery of oil in Pennsylvania. By the early 1900s, major discoveries had been made in Texas, Oklahoma and Kansas and pipelines had become a common method of moving crude oil. However, these early pipelines have long since been decommissioned. They were small diameter pipes that were quite inefficient by today's standards. Leading up to World War II, pipeline companies were operating a maze of these small-diameter pipes laid out in parallel in order to carry enough capacity to fulfill the nation's needs for petroleum. Pump stations were powered by diesel engines, and were usually spaced every 30 miles. Each of these pump stations had to be manned around the clock to keep the system operating properly and the coordination of these multiple operating stations meant there was a lot more opportunity for human error. Following the war, a

technological revolution took place. The need for technological

improvements in oil pipelines was driven by three factors. Pipelines move nearly two-thirds of the oil and petrleum products transported annually. Pipelines are, by far, America's most important petroleum supply line, including crude oil, refined fuel and raw materials. Interstate pipelines deliver over 11.3 billion barrels of petroleum each year. (There are 42 gallons in a barrel.) About 52% of the petroleum transported by pipelines is crude oil and 47% is in the form of refined petroleum products. The cost to transport a barrel of petroleum products from Houston to the New York harbor is about $1, or about 2 1/2 ¢ per gallon at your local gasoline station. The price to transport petroleum products through pipelines does not change, regardless of fluctuations in the price of a gallon of gas. Tell me more about the economic regulation of pipelines The network of crude oil pipelines in the U.S. is extensive. There are approximately 55,000 miles of crude oil trunk lines (usually 8 - 24 inches in diameter) in the U.S. that connect regional markets.

The U.S. also has an estimated 30,000 to 40,000 miles of small gathering lines (usually 2 to 6 inches in diameter) located primarily in Texas, Oklahoma, Louisiana, and Wyoming with small systems in a number of other oil producing states. These small lines gather the oil from many wells, both onshore and offshore, and connect to larger trunk lines measuring from 8 to 24 inches in diameter.

Crude oil is also subdivided in to 'Gathering Lines' and 'Trunk Lines.'

The next group of oil pipelines are those carrying refined petroleum products – gasoline, jet fuel, home heating oil and diesel fuel.

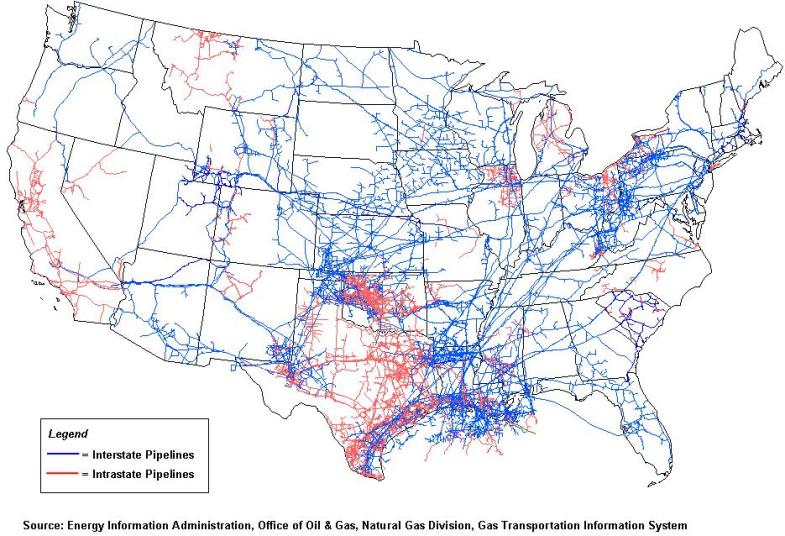

U.S. Natural Gas Pipeline Network

Transporting natural gas from the wellhead to the final customer involves several physical transfers of custody and multiple processing steps. A natural gas pipeline system begins at the natural gas producing well or field. Once the gas leaves the producing well, a pipeline gathering system directs the flow either to a natural gas processing plant or directly to the mainline transmission grid, depending upon the initial quality of the wellhead product. The processing plant produces pipeline-quality natural gas. This gas is then transported by pipeline to consumers or is put into underground storage for future use. Storage helps to maintain pipeline system operational integrity and/or to meet customer requirements during peak-usage periods. Transporting natural gas from wellhead to market involves a series of processes and an array of physical facilities. Among these are:

The Natural Gas Gathering System A natural gas pipeline system begins at a natural gas producing well or field. In the producing area many of the pipeline systems are primarily involved in "gathering" operations. That is, a pipeline is connected to a producing well, converging with pipes from other wells where the natural gas stream may be subjected to an extraction process to remove water and other impurities if needed. Natural gas exiting the production field is usually referred to as "wet" natural gas if it still contain significant amounts of hydrocarbon liquids and contaminants. Under certain conditions some or all of the natural gas produced at a well may be returned to the reservoir in cycling, repressuring, or conservation operations and/or vented and flared. At this stage it is a mixture of methane and other hydrocarbons, as well as some non-hydrocarbons, existing in the gaseous phase or in a solution with crude oil. The principal hydrocarbons normally contained in the natural gas mixture are methane, ethane, propane, butane, and pentane. Typical non-hydrocarbon gases that may be present in reservoir natural gas are water vapor, carbon dioxide, helium, hydrogen sulfide, and nitrogen. Credit:BP, Energy Information Administration, U.S. Department of Energy, CIA, American Gas Association,Association of Oil Pipe Lines |